|

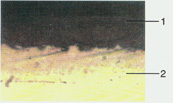

1、Polytetrafluoroethylene and lipophilic fiber mixture 0.01-0.03mm

2、Stainless steel back 0.7-2.3mm

3、Spherical bronze powder 0.2-0.3mm

4、Electroplated layer: 0.005mm thick tin plating layer, or 0.008mm thick copper plating layer | |

| Product description: |

| Sf-1d hydraulic special bearing is a new material designed on the basis of sf-1p in combination with the working principle of oil cylinder and shock absorber. It is more wear-resistant under the condition of no oil. In addition to the advantages of sf-1p, this product is especially suitable for the occasion of frequent reciprocating large lateral force. Its performance is similar to that of foreign DP4. At present, this product gradually replaces sf-1p product, and is suitable for automobile, motorcycle shock absorber and various hydraulic cylinders. Best for use. |

| Technical parameters: |

|

Maximum bearing pressure: 140N / mm2

Applicable temperature range: - 195 ~ + 280 ℃

Maximum sliding speed: 3m / S

Friction coefficient: 0.04 ~ 0.20

Allowable maximum PV value (dry): 3.8n/mm2.m/s

Allowable maximum PV value (oil): 50n / mm2. M / S |

| Application characteristics: |

|

1. The mixture of PTFE and lipophilic fiber can form a good transfer film to protect the grinding shaft.

2. Good wear resistance and low friction coefficient.

3. Good running in performance, no shaft undercut.

4. It can be used in rotation, swing and reciprocating motion.

5. Because it does not contain lead, it can be used in food machinery, medical machinery and other green environmental protection equipment.

6. In addition to the sf-1p features, the products are especially suitable for the occasions with frequent reciprocating motion and large lateral force, and are suitable for the fields of automobile, motorcycle shock absorbers and various hydraulic cylinders. |

| SF-1Dseries chemical properties |

| Bearing type |

In the air |

In vacuum |

In the water |

In steam |

Weak acid |

Medium acid |

Strong acid |

In alkaline solution |

| SF-1D |

good |

good |

good |

good |

difference |

no |

no |

good | |

| SF-1D End friction and wear test |

| Model |

Test time |

Test conditions |

friction coefficient |

Final temperature

(degree Celsius) |

Final wear(mm) |

| lubrication |

speed |

pressure |

| SF-1D |

3hr |

干 |

0.4m/s |

3.5N/mm2 |

0.175 |

98 |

0.012 |

| SF-1D |

3hr |

油 |

0.4m/s |

3.5N/mm2 |

0.054 |

46 |

0.004 | |

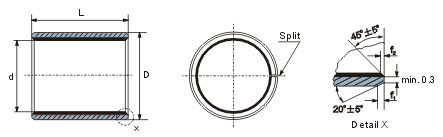

| SF-1D Standard tolerance dimension table |

|

| |

|

|

Matching shaft diameter tolerance |

Matching seat hole tolerance(H7 ) |

Bearing outer diameter tolerance |

Tolerance of inner diameter of bearing after pressing into seat hole |

Wall

thick-

ness

|

f1 |

f2 |

| L0-0.40 |

(d≤φ30 L -0.3

d>φ30 L -0.4) | |

|

6 |

8 |

10 |

12 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

|

6 -0.013

-0.028 |

8 +0.015 |

8 +0.055

+0.025 |

5.990

6.055 |

0.980

1.005 |

0.6 |

0.3 |

0606

|

0608

|

0610

|

|

|

|

|

|

|

|

|

|

8 -0.013

-0.028 |

10 +0.015 |

10 +0.055

+0.025 |

7.990

8.055 |

0806

|

0808

|

0810

|

08012

|

08015

|

|

|

|

|

|

|

|

10 -0.016

-0.034 |

12 +0.018 |

12 +0.065

+0.030 |

9.990

10.058 |

1006

|

1008

|

1010

|

1012

|

1015

|

1020

|

|

|

|

|

|

|

12 -0.016

-0.034 |

14 +0.018 |

14 +0.065

+0.030 |

11.990

12.058 |

1206

|

1208

|

1210

|

1212

|

1215

|

1220

|

1225

|

|

|

|

|

|

13 -0.016

-0.034 |

15 +0.018 |

15 +0.065

+0.030 |

12.990

13.058 |

|

|

1310

|

|

|

1320

|

|

|

|

|

|

|

14 -0.016

-0.034 |

16 +0.018 |

16+0.065

+0.030 |

13.990

14.058 |

|

|

1410

|

1412

|

1415

|

1420

|

1425

|

|

|

|

|

|

15 -0.016

-0.034 |

17 +0.018 |

17+0.065

+0.030 |

14.990

15.058 |

|

|

1510

|

1512

|

1515

|

1520

|

1525

|

|

|

|

|

|

16 -0.016

-0.034 |

18 +0.018 |

18 +0.065

+0.030 |

15.990

16.058 |

|

|

1610

|

1612

|

1615

|

1620

|

1625

|

|

|

|

|

|

17 -0.016

-0.034 |

19 +0.021 |

19 +0.075

+0.035 |

16.990

17.061 |

|

|

1710

|

1712

|

|

1720

|

|

|

|

|

|

|

18 -0.016

-0.034 |

20 +0.021 |

20 +0.075

+0.035 |

17.990

18.061 |

|

|

1810

|

1812

|

1815

|

1820

|

1825

|

|

|

|

|

|

20 -0.020

-0.041 |

23 +0.021 |

23 +0.075

+0.035 |

19.990

20.071 |

1.475

1.505 |

0.6 |

0.4 |

|

|

2010

|

2012

|

2015

|

2020

|

2025

|

2030

|

|

|

|

|

22 -0.020

-0.041 |

25 +0.021 |

25 +0.075

+0.035 |

21.990

22.071 |

|

|

2210

|

2212

|

2215

|

2220

|

2225

|

2230

|

|

|

|

|

24 -0.020

-0.041 |

27 +0.021 |

27 +0.075

+0.035 |

23.990

24.071 |

|

|

|

|

2415

|

2420

|

2425

|

2430

|

|

|

|

|

25 -0.020

-0.041 |

28 +0.021 |

28 +0.075

+0.035 |

24.990

25.071 |

|

|

2510

|

2512

|

2515

|

2520

|

2525

|

2530

|

2540

|

2550

|

|

|

28 -0.020

-0.041 |

32 +0.025 |

32 +0.085

+0.045 |

27.990

28.085 |

1.970

2.005 |

1.2 |

0.4 |

|

|

|

|

2815

|

2820

|

2825

|

2830

|

2840

|

|

|

|

30 -0.020

-0.041 |

34 +0.025 |

34 +0.085

+0.045 |

29.990

30.285 |

|

|

|

3012

|

3015

|

3020

|

3025

|

3030

|

3040

|

|

|

|

32 -0.025

-0.050 |

36 +0.025 |

36 +0.085

+0.045 |

31.990

32.085 |

|

|

|

|

|

3220

|

|

3230

|

3240

|

|

|

|

35 -0.025

-0.050 |

39 +0.025 |

39 +0.085

+0.045 |

34.990

35.085 |

|

|

|

3512

|

3515

|

3520

|

3525

|

3530

|

3540

|

3550

|

|

|

38 -0.025

-0.050 |

42 +0.025 |

42 +0.085

+0.045 |

37.990

38.085 |

|

|

|

|

3815

|

|

|

3830

|

3840

|

|

|

|

40 -0.025

-0.050 |

44 +0.025 |

44 +0.085

+0.045 |

39.990

40.085 |

|

|

|

4012

|

|

4020

|

4025

|

4030

|

4040

|

4050

|

|

|

Matching shaft diameter tolerance |

Matching seat hole tolerance(H7 ) |

Bearing outer diameter tolerance |

Tolerance of inner diameter of bearing after pressing into seat hole |

Wall

thick-

ness |

f1 |

f2 |

L0-0.40 |

|

20 |

25 |

30 |

40 |

50 |

60 |

70 |

80 |

100 |

115 |

|

45 -0.025

-0.050 |

50 +0.025 |

50 +0.085

+0.045 |

44.990

45.105 |

2.460

2.505 |

1.8 |

0.6 |

4520

|

4525

|

4530

|

4540

|

4550

|

|

|

|

|

|

|

50 -0.025

-0.050 |

55 +0.030 |

55 +0.100

+0.055 |

49.990

50.110 |

5020

|

|

5030

|

5040

|

5050

|

5060

|

|

|

|

|

|

55 -0.030

-0.060 |

60 +0.030 |

60 +0.100

+0.055 |

54.990

55.110 |

|

|

5530

|

5540

|

5550

|

5560

|

|

|

|

|

|

60 -0.030

-0.060 |

65 +0.030 |

65 +0.100

+0.055 |

59.990

60.110 |

|

|

6030

|

6040

|

6050

|

6060

|

6070

|

|

|

|

|

65 -0.030

-0.060 |

70 +0.030 |

70 +0.100

+0.055 |

64.990

65.110 |

|

|

6530

|

6540

|

6550

|

6560

|

6570

|

|

|

|

|

70 -0.030

-0.060 |

75 +0.030 |

75 +0.100

+0.055 |

69.990

70.110 |

|

|

|

7040

|

7050

|

7060

|

7070

|

7080

|

|

|

|

75 -0.030

-0.060 |

80 +0.030 |

80 +0.100

+0.055 |

74.990

75.110 |

|

|

7530

|

7540

|

7550

|

7560

|

7570

|

7580

|

|

|

|

80 -0.030

|

85 +0.035 |

85 +0.120

+0.070 |

80.020

80.155 |

2.440

2.490 |

1.8 |

0.6 |

|

|

|

8040

|

8050

|

8060

|

8070

|

8080

|

80100

|

|

|

85 -0.035 |

90 +0.035 |

90 +0.120

+0.070 |

85.020

85.155 |

|

|

|

8540

|

|

8560

|

|

8580

|

85100

|

|

|

90 -0.035 |

95 +0.035 |

95 +0.120

+0.070 |

90.020

90.155 |

|

|

|

9040

|

9050

|

9060

|

|

9080

|

90100

|

|

|

95 -0.035 |

100 +0.035 |

100 +0.120

+0.070 |

95.020

95.155 |

|

|

|

|

9550

|

9560

|

|

9580

|

95100

|

|

|

100 -0.035 |

105 +0.035 |

105 +0.120

+0.070 |

100.020

100.155 |

|

|

|

|

10050

|

10060

|

|

10080

|

|

100115

|

|

105 -0.035 |

110 +0.035 |

110 +0.120

+0.070 |

105.020

105.155 |

|

|

|

|

|

10560

|

|

10580

|

|

105115

|

|

110 -0.035 |

115 +0.035 |

115 +0.120

+0.070 |

110.020

110.155 |

|

|

|

|

|

11060

|

|

11080

|

|

110115

|

|

120 -0.035 |

125 +0.040 |

125 +0.170

+0.100 |

120.070

120.210 |

2.415

2.465 |

1.8 |

0.6 |

|

|

|

|

|

12060

|

|

12080

|

112100

|

|

|

125 -0.040 |

130 +0.040 |

130 +0.170

+0.100 |

125.070

125.210 |

|

|

|

|

|

12560

|

|

|

125100

|

125115

|

|

130 -0.040 |

135 +0.040 |

135 +0.170

+0.100 |

130.070

130.210 |

|

|

|

|

|

13060

|

|

13080

|

130100

|

|

|

140 -0.040 |

145 +0.040 |

145 +0.170

+0.100 |

140.070

140.210 |

|

|

|

|

|

14060

|

|

14080

|

140100

|

|

|

150 -0.040 |

155 +0.040 |

155 +0.170

+0.100 |

150.070

150.210 |

|

|

|

|

|

15060

|

|

15080

|

150100

|

|

|

160 -0.040 |

165 +0.040 |

165 +0.170

+0.100 |

160.070

160.210 |

|

|

|

|

|

16060

|

|

16080

|

160100

|

160115

|

|

180 -0.040 |

185 +0.046 |

185 +0.210

+0.130 |

180.070

180.216 |

|

|

|

|

|

|

|

|

|

|

18080

|

180100

|

|

|

190 -0.046 |

195 +0.046 |

195 +0.210

+0.130 |

190.070

190.216 |

|

|

|

|

|

|

|

19080

|

190100

|

|

|

200 -0.046 |

205 +0.046 |

205 +0.210

+0.130 |

200.070

200.216 |

|

|

|

|

|

20060

|

20080

|

200100

|

|

|

220 -0.046 |

225 +0.046 |

225 +0.210

+0.130 |

220.070

220.216 |

|

|

|

|

|

|

|

22080

|

220100

|

|

|

250 -0.046 |

255 +0.052 |

255 +0.260

+0.170 |

250.070

250.222 |

|

|

|

|

|

|

|

25080

|

250100

|

|

|

260 -0.052 |

265 +0.052 |

265 +0.260

+0.170 |

260.070

260.222 |

|

|

|

|

|

|

|

26080

|

260100

|

|

|

280 -0.052 |

285 +0.052 |

285 +0.260

+0.170 |

280.070

280.222 |

|

|

|

|

|

|

|

28080

|

280100

|

|

|

300 -0.052 |

305 +0.052 |

305 +0.260

+0.170 |

300.070

300.222 |

|

|

|

|

|

|

|

30080

|

300100

|

| |